Methods

Density Functional Theory (DFT) is a powerful computational method used to study the structural, electronic, and phononic properties of molecules and solids. DFT simplifies the quantum-mechanical problem of N electrons interacting with each other by focusing on the electron density, which contains all the essential information about a system’s properties. This approach allows for accurate predictions of ground-state properties, such as energy and structural stability, while significantly reducing computational costs.

We use DFT for modeling and analyzing two-dimensional (2D) materials, adsorption of molecules on 1D and 2D materials, and novel carbon-based planar lattices. In addition, we use further computational methods that include many-body interactions for prediction of, e.g., excitonic states.

In optical spectroscopy, we excite a sample with laser light and detect the spectrum of the scattered/emitted light. Raman scattering is inelastic light scattering that gives insights into the crystal structure, defects and disorder, vibrational and electronic properties, or electron-phonon coupling. In photoluminescence (PL) spectroscopy, we investigate optical properties such as excitons, band gaps, defect-induced emission, but also structural properties and phase transitions. Additional insight about excited states and energy transfer in heterostructures is obtained through resonant excitation by using multiple/tunable excitation wavelengths.

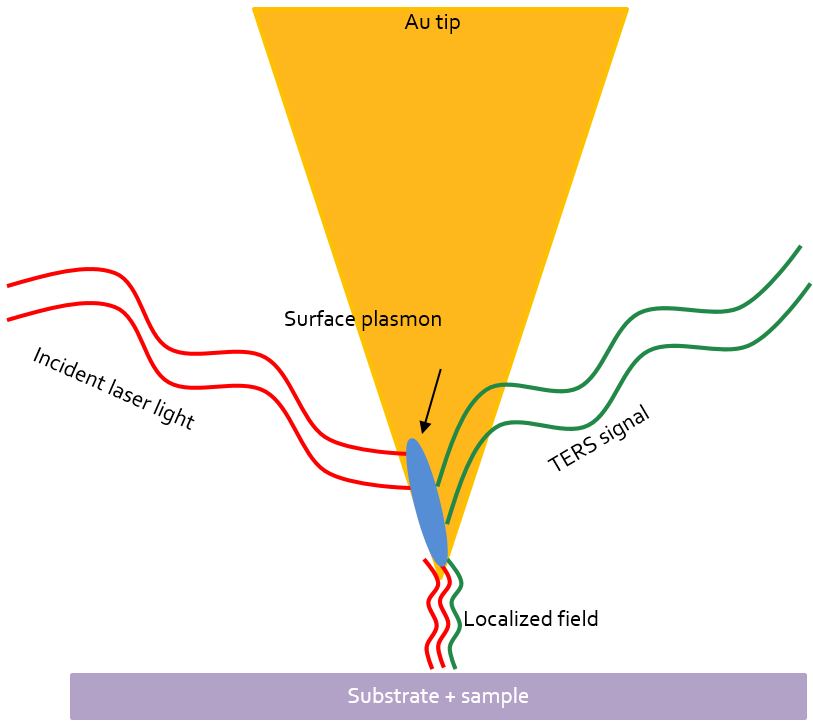

Tip-enhanced Raman spectroscopy (TERS) and photoluminescence (TEPL) makes use of the enhancement of the incoming and emitted light through a metallic tip close to the sample surface. This leads to a strongly enhanced spatial resolution on the order of tens of nanometers, well beyond the diffraction-limited spatial resolution in optical microscopy.

Atomic force microscopy (AFM) is a powerful imaging technique used to analyze surface topography at the nanoscale by measuring the interaction forces between a sharp tip and the surface of a sample. Kelvin probe force microscopy (KPFM), a variation of AFM, measures the local surface potential of a sample by detecting variations in electrostatic forces, offering insights into work function differences and charge distributions. We use AFM and KPFM (at ambient conditions) to investigate novel materials such as TMDCs, graphene and carbon nanotubes as well as molecular adsorption on surfaces.

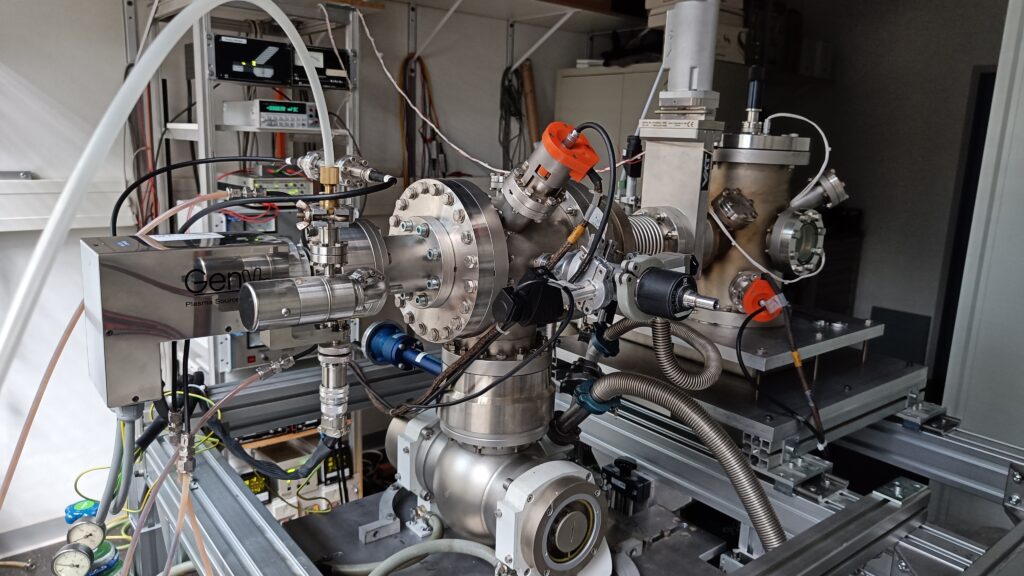

Ion irradiation can be used for a controlled creation of defects (atomic vacancies) in 2D materials. We extract ions, for example Ar+, with an accelerating voltage of up to 2kV directed towards the sample, whereby single atoms can be removed from the material. By varying the dose, we can achieve different defect densities. Our research focuses on the impact of these defects on the optical and vibrational properties of 2D materials.

Further, this technique can be used for graphitization of polymer surfaces, where we can produce different thicknesses between one and tens of nanometers of a graphitized layer on various organic materials. The resulting layer can behave as an insulator or as a semimetal, which can be precisely controlled by the process parameters.

Exfoliation:

Mechanical exfoliation is a common approach where adhesive tape is used to peel off thin layers of 2D materials. The weak van der Waals forces between the layers in materials like graphite, hBN, or TMDCs allow to isolate single or few atomic layers from bulk crystals. We use this process for the preparation of high-quality 2D materials, van-der-Waals heterostructures and twisted structures by stacking individual layers on top of each other.

Chemical vapor deposition (CVD):

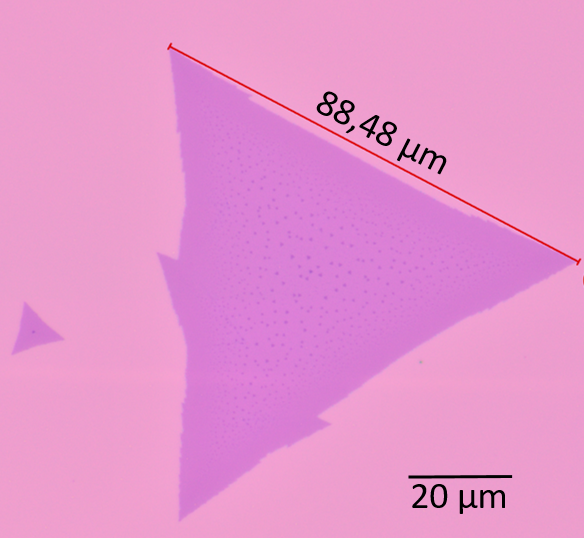

Chemical vapor deposition (CVD) is a process for growing thin layers of material, in our research, monolayers of sulfur-based TMDCs. For this purpose, transition metal compounds and sulfur, both in powder form, are heated until evaporation/sublimation into a carrier gas. Chemical reactions take place at this point resulting in the desired TMDC, which is then deposited on a substrate in single- or few-layer form.